malipoklon

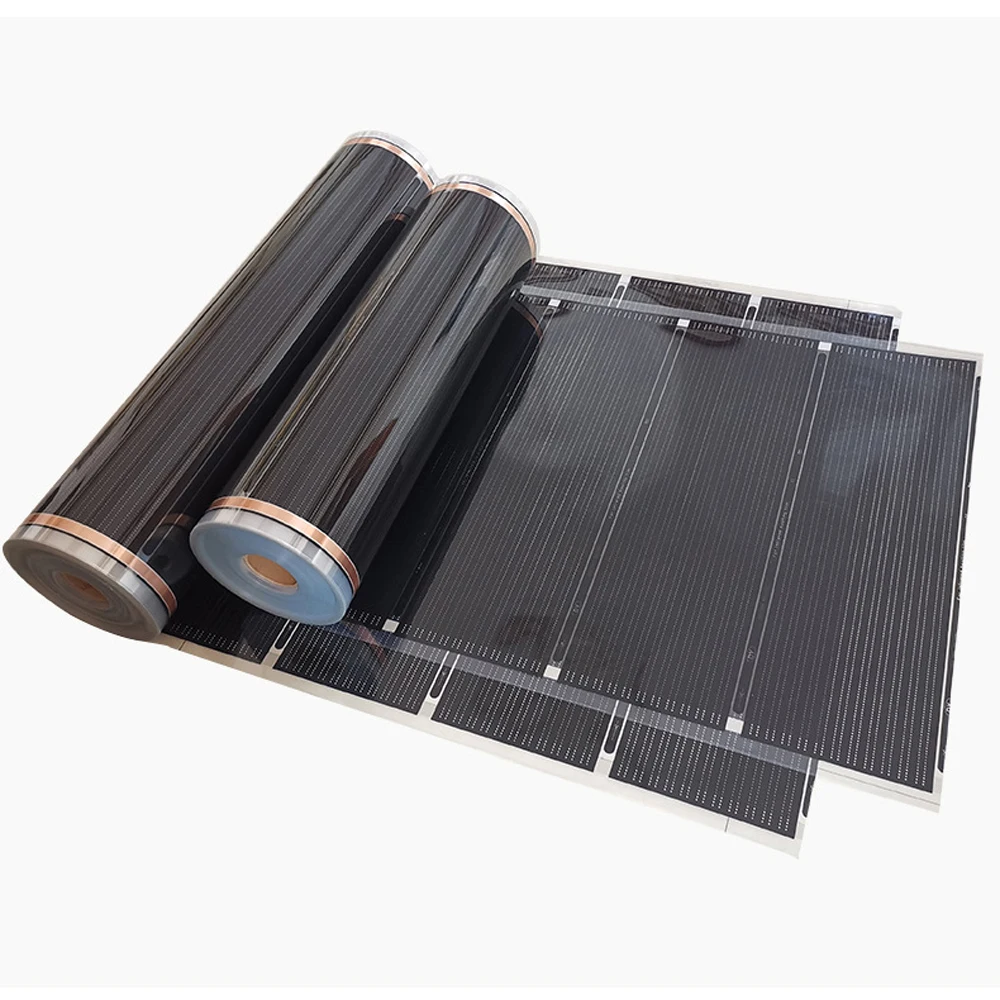

Infrared Underfloor Heating Film

Infrared Underfloor Heating Film

Couldn't load pickup availability

Product parameter

Working voltage: 200~240V 50/60Hz

Rated power: 80W/m2 ±10%

Max surface temperature: 32° C

Melting Point Film: 130 ° C

Thichness: 0.338mm

Width: 50cm

Infrared radiation: 90,4%

Wave Length: 5-20 um

Maximum film length for one row: 1100W

Electromagnetic field-almost none

400W high-power electric heating film, suitable for high-temperature products such as carbon crystal heating pad heating element materials, high-temperature yoga studios, and steam rooms.

Superiority of Heating Film Heating System:

Infrared heating is one of the healthiest and most modern method of heating, which uses a similar thermal properties as the sun itself. Infra red rays directly heat people, walls and objects, and then the air is heated from them. In traditional radiator heating it leads to heating and drying the air. Warm air flows up and first heats the top of the room and then low-lying objects, people and so on.

When using infra red heating, the air temperature is usually lower by 3-4 ° C, as in a room with traditional heating it to achieve a comparable feeling of warmth. Lowering the air temperature by 1 ° C can save up to 5-6% of energy.

Suitable for high temperature products such as carbon crystal heating pad heating element materials, high temperature yoga studios, sweat steam rooms, etc.

Packing list:

1pcs heating film

Features:

- Infra panels have an efficiency of 98%, an average energy saving is 30%

- Infra heating does not cause dust dispersion

- It creates a healthy environment, destroys bacteria

- Ensures uniform temperature in whole room

- Clean, noiseless, maintenance-free operation and space-saving

- Easy control and operation with thermostats

- Easy installation.

Reminder:

1.Maximum film length for one row.

The maximum carrying power of the heating film is 1100W, but we can solve it in parallel.

For example,

If you buy 80W heating film, the length of a single heating film needs to be <27m,

2.When installing, do not overlap each film. Always keep 1~3cm distance between films. and keeps 10~20cm distance between the way and films.

Detailed description of the wiring

1. The white gap in the middle can be cut.

2. Clip the electric heating film clip to the copper strip part.

3. Use pressure pliers to compress the wiring.

4. Seal the wiring part with waterproof glue.

5. Seal the other side with cement.

6. Seal the other ends of the electric heating film with sealing glue.

Installation Notes

1. Floor paving steps: extruded board ➔ reflective film ➔ electric heating film ➔ non-woven fabric ➔ floor.

2. Tile paving steps: extruded board ➔ reflective film ➔ connected to the electric heating film and put in a waterproof sealed bag ➔ waterproof layer ➔ wipe cement and tile.

Electric heating film construction process

Clean the ground ➔ Lay the extruded board ➔ Lay the reflective film ➔ Lay the electric heating film and wire it ➔ Connect the thermostat and stick the thermostat sensor probe ➔ Heat test ➔ Lay non-woven fabric ➔ Lay the floor